The windscreen had been attached to the roll bar and forward fuselage skin using sikaflex 295 previously. I scuffed up all the surfaces that would be covered with fiberglass and waxed the canopy forward 2 inches with mold release wax before closing it tight. I first did a 7 layer layup starting with a 1/2″ wide then increasing in 1/4″ increments to a width of 2 inches. Once that layup was done I covered it with peel and ply cloth (dacron material) and rolled it with my fibreglass roller to saturate the cloth with excess resin and work out any remaining bubbles or voids.

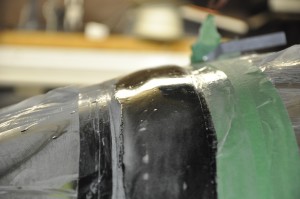

The windscreen had been attached to the roll bar and forward fuselage skin using sikaflex 295 previously. I scuffed up all the surfaces that would be covered with fiberglass and waxed the canopy forward 2 inches with mold release wax before closing it tight. I first did a 7 layer layup starting with a 1/2″ wide then increasing in 1/4″ increments to a width of 2 inches. Once that layup was done I covered it with peel and ply cloth (dacron material) and rolled it with my fibreglass roller to saturate the cloth with excess resin and work out any remaining bubbles or voids.  Once the resin cured I removed the peel and ply strips and went to work sanding and sanding. I sand right down to the thickness of the electrical tape which defines the edges of the fibreglass fairing. This works really well for producing a thin straight finished edge where the fairing intersects fuselage and windscreen.

Once the resin cured I removed the peel and ply strips and went to work sanding and sanding. I sand right down to the thickness of the electrical tape which defines the edges of the fibreglass fairing. This works really well for producing a thin straight finished edge where the fairing intersects fuselage and windscreen.

I repeated the process for the rollbar fairing, except the width of the layups varied. First a 2 inch wide strip, then decreasing widths to 1 inch wide and a final 2 inch strip again to smooth it out. Once cured I cut the trailing edge of the fairing to allow a 1 inch overhang on the canopy. Sure was glad I put mold release wax and mylar packing tape on the canopy before doing the layup. It took a bit of work to make the canopy release the grip the layup had on it. I eventually used a feeler guage to get between the two to get a release going.

I repeated the process for the rollbar fairing, except the width of the layups varied. First a 2 inch wide strip, then decreasing widths to 1 inch wide and a final 2 inch strip again to smooth it out. Once cured I cut the trailing edge of the fairing to allow a 1 inch overhang on the canopy. Sure was glad I put mold release wax and mylar packing tape on the canopy before doing the layup. It took a bit of work to make the canopy release the grip the layup had on it. I eventually used a feeler guage to get between the two to get a release going.