For a variety of reasons, I have decided to stray from the standard Vans method of attaching the canopy and windscreen to their respective frames. I know its a time tested procedure and there are thousands of RVs flying that have been built this way. I also know that the extreme temperature swings we see up here in Canada will test the limit of the polycarbonate and steel tube frame bond when a rivet is used. The polycarbonate will be the one who gives and resulting stress cracks will inevitably appear. It happened on my CH701 and it will happen on the RV9A.

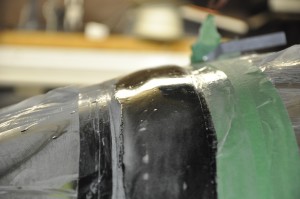

Vans chose to drill and then rivet the canopy to the frame and side skirts. I have decided to glue the canopy to the frame using a modern adhesive system based upon the product called Sikaflex 295UV. This product is used extensively in the marine industry for attaching windows to frames in a wide range of boats, ships etc. The product is UV stabilized and available in either white or black color. The tubes of Sikaflex 295UV can be purchased from a variety of marine retail outlets. It is time limited (best before) so most dealers don’t keep it on the shelf and have to order it in for you. The most expensive part of this process is the primer product and cleaner product that must be used to prepare the parts to be joined.

I am not breaking new ground using Sikaflex, many others have taken this path. I relied on a number of other builder’s web sites to get the process straight in my mind. A good place to look is Bret’s RV9A builders log under the canopy posts. I checked back with Bret in January of 2012 to see how the Sikaflex was holding up and he reported that it was as good as new after 3 years and a couple hunderd hours of flight. I have heard of a few problems during the preparation phase of this task with cleaner getting somewhere it was not supposed to be and fogging the surface of the canopy. This would be remedied by taking care during the application of the prep solutions and protecting the surfaces where you don’t want it to go.

UPDATE

The summer has passed and I have failed at keeping my building log current. Too much to do on the ranch this time of the year plus a new engine upgrade in the CH701 made for little log update time.

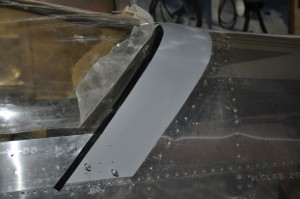

I did manage to finish attaching the canopy to the frame with Sikaflex and completed the attachment of the canopy skirt and canopy latch system. The canopy turned out great, slides freely in the tracks and locks nicely in place. The rear canopy locking pins are a bit tight in the delron blocks but that will loosen over time so no worries there. I must now make sure I have completed every task I can think of forward of the instrument panel so the forward cabin skin can be riveted in place. Once in place, any work forward of the instrument panel becomes an upside down task, not particularly fun.

I’ll post a picture of the finished canopy work shortly.

It seemed that the filling and sand cycle would never end, but all good things must come to an end and so did this task. A few coats of high fill sandable primer and touchup with bondo scratch filler and I was finished with this piece. I know there will be another final touchup session before final paint goes on, but this is it for now.

It seemed that the filling and sand cycle would never end, but all good things must come to an end and so did this task. A few coats of high fill sandable primer and touchup with bondo scratch filler and I was finished with this piece. I know there will be another final touchup session before final paint goes on, but this is it for now.