This is the latest release of the TC4 controller which is used to monitor, display and alarm on data and status from both of the Precision Airmotive Eagle ECUs (engine control units). The TC4 also has a GPS module which combines flight data with engine data for the best of tuning information. The data is stored in a micro SD memeory card. The TC4 has ethernet port, USB programming port, USB memory stick port and two serial ports for RS232 and RS485 communications. The pilot interface is a full color touch screen with impressive graphics and screen update times.

This is the latest release of the TC4 controller which is used to monitor, display and alarm on data and status from both of the Precision Airmotive Eagle ECUs (engine control units). The TC4 also has a GPS module which combines flight data with engine data for the best of tuning information. The data is stored in a micro SD memeory card. The TC4 has ethernet port, USB programming port, USB memory stick port and two serial ports for RS232 and RS485 communications. The pilot interface is a full color touch screen with impressive graphics and screen update times.

The TC4 communicates with both Eagle ECU A and ECU B via a RS485 Modbus data link. Each ECU is polled every two seconds and data is placed in the TC4 memory for processing. I have already bench tested the data link between the ECU and TC4 and now I am working on displays for all the various data types that are available.

The TC4 communicates with both Eagle ECU A and ECU B via a RS485 Modbus data link. Each ECU is polled every two seconds and data is placed in the TC4 memory for processing. I have already bench tested the data link between the ECU and TC4 and now I am working on displays for all the various data types that are available. In addition to the GPS and Eagle ECU data, the TC4 can receive 4 analog inputs from various instruments, 12 digital inputs from switches or sensors and it has 6 relay outputs for driving lights or operating loads such as relays. The TC4 can also be expanded via its CANBUS port to monitor and control a large number of other devices which use this protocol.

In addition to the GPS and Eagle ECU data, the TC4 can receive 4 analog inputs from various instruments, 12 digital inputs from switches or sensors and it has 6 relay outputs for driving lights or operating loads such as relays. The TC4 can also be expanded via its CANBUS port to monitor and control a large number of other devices which use this protocol.

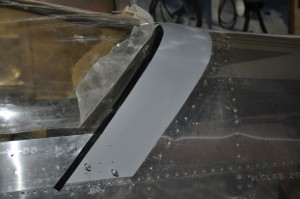

I will field test this controller in the CH701 prior to RV9A flight to ensure its screen design and operation is easy and intuitive to use.