There are two techniques used in the aluminum skin polishing, the first being compound polishing and the second being orbital.

Compound polishing uses a circular wool buffing pad on either a 3/4″ variable speed electric drill or a made for purpose low speed polisher. The two things most desireable in this process are speed control and power. The 10 inch wool pad can use up a fair bit of power and you need a place to put both your hands when you are compounding so forget about using a 1/4″ drill. I used an older Black and Decker polisher for a while for the wing surfaces. It has too high of a speed, >2000 rpm so its not the best when doing smaller parts or working around brackets and hinges. I got into using a Black and Decker 3/4″ drill which has a beefy side handle. It had become my tool of choice for compounding.

I used an older Black and Decker polisher for a while for the wing surfaces. It has too high of a speed, >2000 rpm so its not the best when doing smaller parts or working around brackets and hinges. I got into using a Black and Decker 3/4″ drill which has a beefy side handle. It had become my tool of choice for compounding.

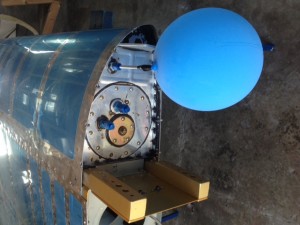

Compound polishing is used to remove the mill marks from the metal, smooth out scratches and generally prepare the metal for the fine polishing to follow. The polisher is drawn across (or down) the surface in one continious action. No back and forth or circle motion allowed. You can see in the picture above, the swirl lines left across the surface of this flap. These are removed in the next step with the orbital polisher.