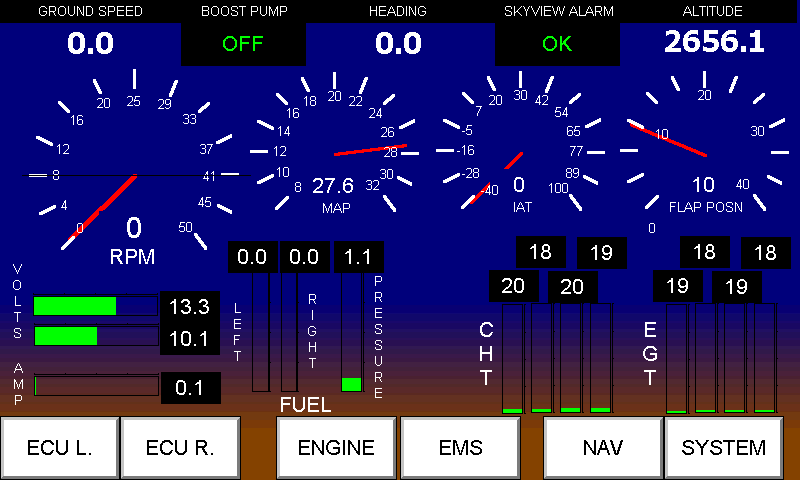

What started out as a small 4″ monocolor display has grown into a high resolution color touch screen display with super bright graphics. It has a brightness rating of 1000 nits which is slightly lower than the 10 inch Dynon Skyview it will be sitting beside in my panel. I have custom built all the displays and logic programs that provide a list of features I’ll try and explain in upcoming posts. The main drive for building this display was to set up a better interface to the Precision Eagle ECU than what was delivered in the box. If you have an Eagle, you know what I mean. This system communicates with both the left and right ECU via a communications driver I configured. This system also receives Skyview Engine Monitor data via a serial data link. Updates are every second. Final interface is with a Garmin GPS module for back up position data and some basic navigation features with a destinations data base. There are many more features built in that I will expand on as web time allows. This is not a commercial venture, just something I crafted for my project and I will share with others who have similar needs.