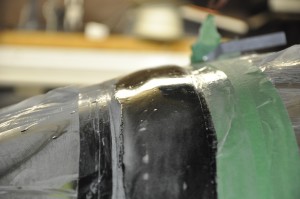

A number of folks are going away from using the kit supplied aluminum rear cover strips to fibreglass layups instead. This method complements the use of sikaflex for canopy-frame attachment as once the cove strip is finished, its glued in place with sikaflex, eliminating the rivets and hole drilling in canopy and frame. The construction process is the same as that used for the windscreen fairing, the strips are 6.5 to 7 inch wide and the initial layup of 6 glass layers is easily done in a hour and a couple of batches of resin. Before starting layup, mylar packing tape is used to cover the gap between the canopy and the rear fuselage skin.

A number of folks are going away from using the kit supplied aluminum rear cover strips to fibreglass layups instead. This method complements the use of sikaflex for canopy-frame attachment as once the cove strip is finished, its glued in place with sikaflex, eliminating the rivets and hole drilling in canopy and frame. The construction process is the same as that used for the windscreen fairing, the strips are 6.5 to 7 inch wide and the initial layup of 6 glass layers is easily done in a hour and a couple of batches of resin. Before starting layup, mylar packing tape is used to cover the gap between the canopy and the rear fuselage skin.

The layup is complete and this weekend I will start sanding and filling it before removing from the aircraft. This method is sand and fill tedious but rather easy and stress free compared to the difficulties I have heard of using a metal skin.