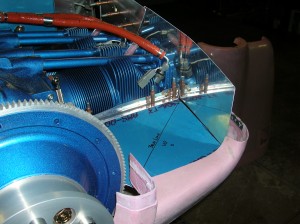

An out of province wedding the week before Christmas followed by the hub-bub of Christmas activities halted all buildng for a few weeks. Baffle work back in full production mode, oil cooler mounted, rework on the aft baffles to accomodate the Fuel Distribution block. It seems like the baffles have taken forever to finish but I am nearing completion as the rubber seal strips finally go in place.

An out of province wedding the week before Christmas followed by the hub-bub of Christmas activities halted all buildng for a few weeks. Baffle work back in full production mode, oil cooler mounted, rework on the aft baffles to accomodate the Fuel Distribution block. It seems like the baffles have taken forever to finish but I am nearing completion as the rubber seal strips finally go in place.

Author Archives: aviationcam

Eagle ECU and Skyview Power Distribution

Here is a link to the schematic for the Eagle and Skyview power distribution

Fitting Baffles

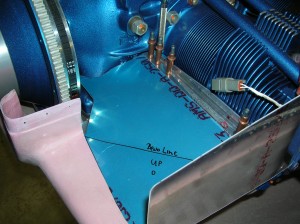

Spent the evening working away on the aft baffle pieces. What would normally be straight forward installation is complicated by the Precision fuel distribution assembly. I worked away at it until I had a nice baffle fit around the large filter cannister. I’ll add a few nutplates and a removable piece to fill in the hole under the filter. I should be able to find a rubber or plastic channel to protect the filter from the baffle plate. The fuel pressure transducers on the fuel distribution block will need to be repositioned as their connector plugs are too close to the baffle.

Spent the evening working away on the aft baffle pieces. What would normally be straight forward installation is complicated by the Precision fuel distribution assembly. I worked away at it until I had a nice baffle fit around the large filter cannister. I’ll add a few nutplates and a removable piece to fill in the hole under the filter. I should be able to find a rubber or plastic channel to protect the filter from the baffle plate. The fuel pressure transducers on the fuel distribution block will need to be repositioned as their connector plugs are too close to the baffle.

ECU Components return

The Precision system comes without any wiring components. After you mount the ECU, coils and PMU, you fill out a wiring order form, complete with all the lengths of the various sensor, ignition and communication cables. Once I submitted that form I was contacted by Precision and asked for the firmware revision information on my various components. Turned out I had old stock on the ECU and PMU and had to ship them back for updates. Today the componets returned along with the completed cables, custom made to my specifications.

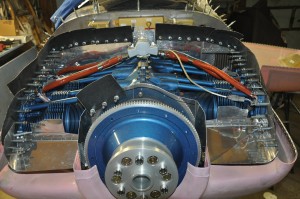

coils and PMU, you fill out a wiring order form, complete with all the lengths of the various sensor, ignition and communication cables. Once I submitted that form I was contacted by Precision and asked for the firmware revision information on my various components. Turned out I had old stock on the ECU and PMU and had to ship them back for updates. Today the componets returned along with the completed cables, custom made to my specifications. I was keen to confirm that I had made the correct measurements and that Precision had followed them. I was not disappointed, the workmanship was excellent and everything fit as planned. The attached photos are not finished installation, only a first fitup.

I was keen to confirm that I had made the correct measurements and that Precision had followed them. I was not disappointed, the workmanship was excellent and everything fit as planned. The attached photos are not finished installation, only a first fitup.

Epoxy the hinge lines

Todays task was the fastening of the cowl hinges to the upper and lower cowl halves. Surfaces were scrubbed and sanded on the cowls and hinges. Epoxy resin was mixed with microspheres to make a slurry. This mixture buttered on the cowl surfaces where the hinges attach. Clecoed in place and then riveted for final attachment with flush rivets. The epoxy mixture oozed out of the holes I had drilled for that purpose. So far all is going according to plan. Tomorrow it will be back to work on the baffles

Surfaces were scrubbed and sanded on the cowls and hinges. Epoxy resin was mixed with microspheres to make a slurry. This mixture buttered on the cowl surfaces where the hinges attach. Clecoed in place and then riveted for final attachment with flush rivets. The epoxy mixture oozed out of the holes I had drilled for that purpose. So far all is going according to plan. Tomorrow it will be back to work on the baffles