Good bye piano hinge, not all of them on the cowl but definitely the one across the top cowl section at the firewall. This thing has been a real pain from the get-go to feed the retaining wire into. I reduced the wire diameter to .090 wire from .120 as this will ease installation. Still a pain feeding wire thru a 4 inch square hole. Many RV builders choose the Skybolt Fastener system for part or all of their cowl retention system. A little on the spendy side at $200 for a complete kit with 16 fasteners, but over the long haul I am sure it will be worth it.

Good bye piano hinge, not all of them on the cowl but definitely the one across the top cowl section at the firewall. This thing has been a real pain from the get-go to feed the retaining wire into. I reduced the wire diameter to .090 wire from .120 as this will ease installation. Still a pain feeding wire thru a 4 inch square hole. Many RV builders choose the Skybolt Fastener system for part or all of their cowl retention system. A little on the spendy side at $200 for a complete kit with 16 fasteners, but over the long haul I am sure it will be worth it.

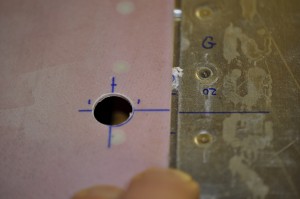

The kit comes with 18 aluminum tabs which have one end joggled to allow overlap with the adjacent tab. The spacing of the tabs is tweeked to make best use of the 16 fasteners (two spare tabs to screw up are provided). I spaced my tabs 3.5 inches (c-c) apart on the sides and then reduced the spacing to 3 inches (c-c) across the top of the cowl. Once riveted to the firewall flange, a number of Cleco inserts are taped in position (every third tab) and the cowl is put back in place. I installed a few trouble lights under the cowl and turned off the shop lights to allow me to see the cleco insert hole and then carefully drill the #20 hole for a cleco. I found this technique was OK but still not as accurate as I should have for a perfect fit. I removed the top cowl, and marked the exact position of the tab hole, its centre line and distance in MM from the forward fuselage skin. I replaced the cowl and then transfered these measurements to the cowl, drilled a pilot hole and then used the unibit to open the hole up to one size under the finished size of (CONFIRM). I used a twist drill to go to final size. At right the final drilling is almost complete and I am checking for accuracy.

The skybolts come with two types of fastening flanges, one fixed and one floating. It is suggested to use three floaters on  the each side and the fixed across the top. Other builders have reported this doesn’t make a difference. I chose to use the floating plates where my cowl fastener hole was not perfectly aligned with the tab hole. The fasteners are then flush riveted to the firewall tabs. That proved to be difficult in a few of the tight spots around the motor mounts and above the engine ECU. The No-hole rivet squeezer yolk was able to catch those rivets that the regular yolk was too fat to reach.

the each side and the fixed across the top. Other builders have reported this doesn’t make a difference. I chose to use the floating plates where my cowl fastener hole was not perfectly aligned with the tab hole. The fasteners are then flush riveted to the firewall tabs. That proved to be difficult in a few of the tight spots around the motor mounts and above the engine ECU. The No-hole rivet squeezer yolk was able to catch those rivets that the regular yolk was too fat to reach.