Here is the finished fastener riveted into the tab. Its a nicely engineered fastener. The internal locking ring of the fastener is threaded so its locking depth may be adjusted to compensate for varying fibreglass thickness. The end result is a flush fitting fastener on the cowl surface with little variation from fastener to fastener.

Here is the finished fastener riveted into the tab. Its a nicely engineered fastener. The internal locking ring of the fastener is threaded so its locking depth may be adjusted to compensate for varying fibreglass thickness. The end result is a flush fitting fastener on the cowl surface with little variation from fastener to fastener.

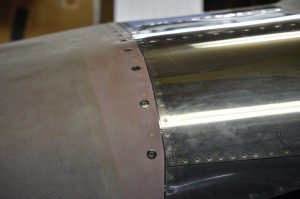

I will now be able to prime the cowl and get onto the next hundred items (who is counting) before final inspection day. The finished product is pretty good looking.  The gap between the cowl and forward fuselage skin is a bit wider than I was shooting for but it is the same width for the length of the joint. Once paint is on the gap will shrink and ther ewill be no chance of the cowl rubbing on the fuselage skin and making the paint flake off.

The gap between the cowl and forward fuselage skin is a bit wider than I was shooting for but it is the same width for the length of the joint. Once paint is on the gap will shrink and ther ewill be no chance of the cowl rubbing on the fuselage skin and making the paint flake off.